Venturi

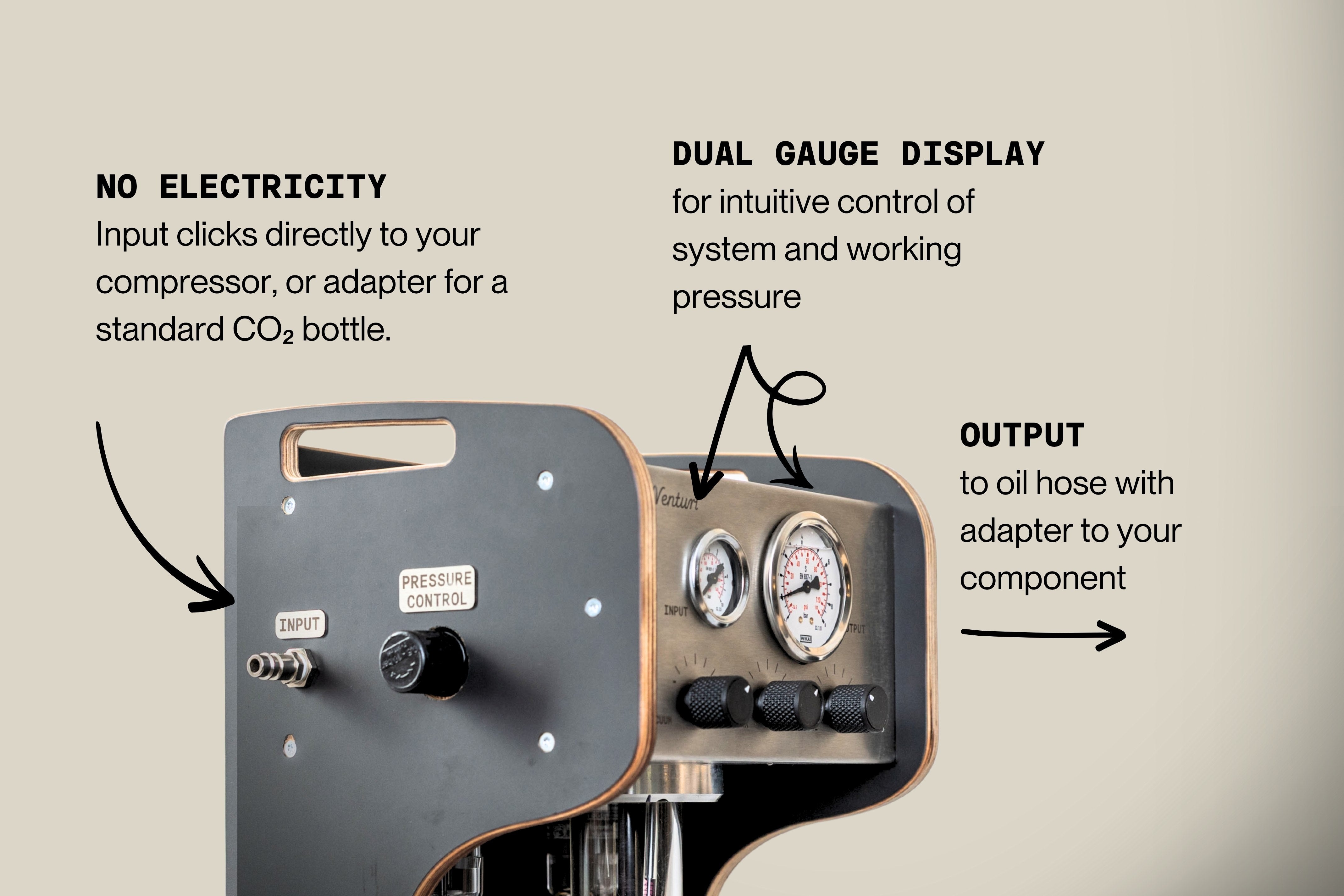

The VENTURI is your all-in-one tool for MTB suspension service. Whether air shock, coil shock, or fork cartridge — you can vacuum-bleed and refill your components with precision. All fully pneumatic, powered only by compressed air or CO₂, with no electricity required.

Efficient & clean: Controlled negative pressure degasses the suspension fluid and extracts trapped air from dampers, ensuring consistent damping performance and a highly sensitive initial stroke. The interchangeable, transparent tanks provide full visual control of degassing, oil color, viscosity, contamination, and foam formation. You can run the vacuum cycle exactly as long as needed until the oil is completely bubble-free.

Flexible & compact: Works in any setup — workshop compressor, mobile CO₂ bottle, or minimal home garage. The standard NW7 coupling makes it universally compatible. Its compact footprint fits into any toolbox, making it ideal for workshops, trail mechanics, and dedicated DIY riders.

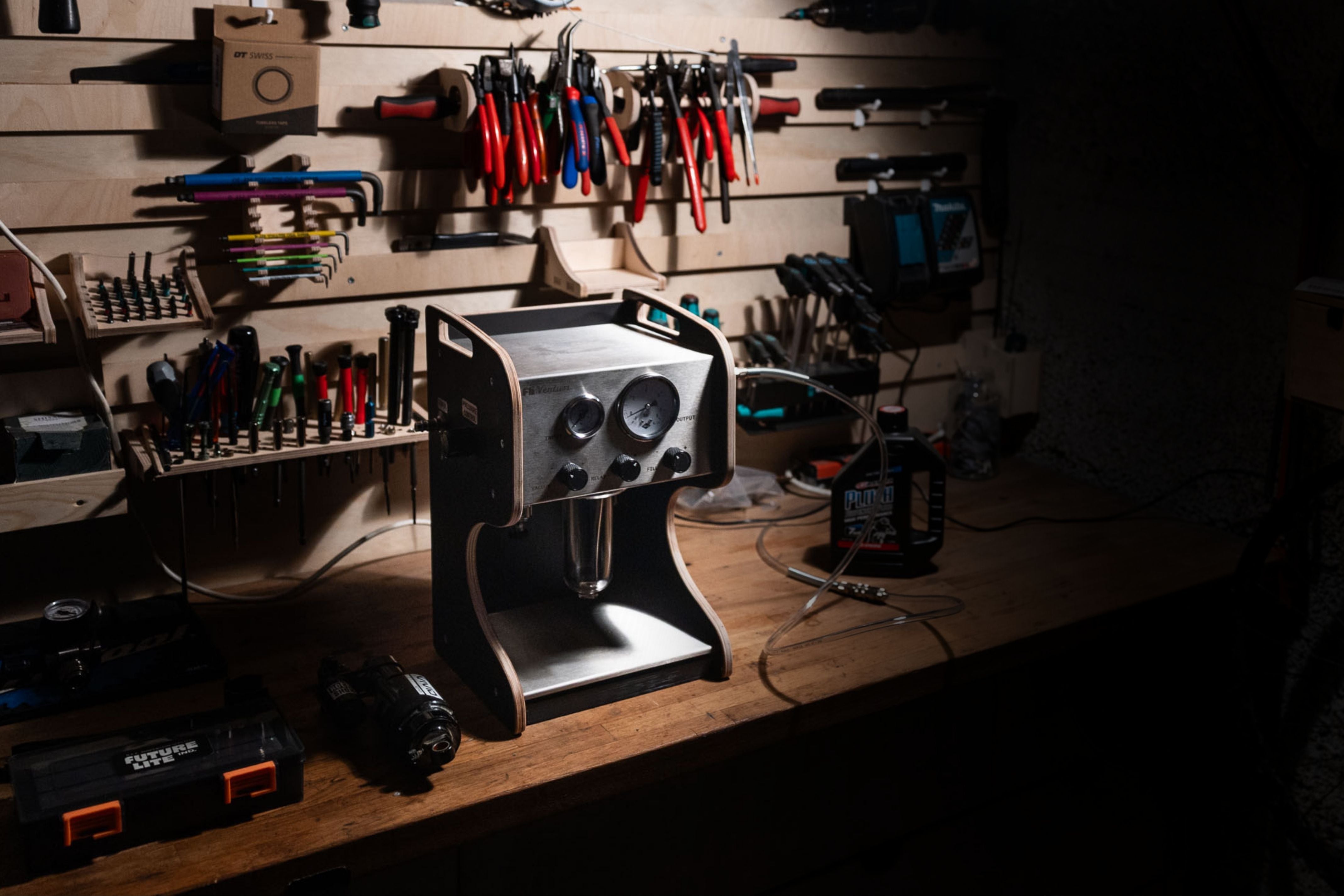

Robust & durable: Built from anti-fingerprint, scratch-resistant Fenix® birch plywood and brushed stainless steel. All interfaces use corrosion-resistant anodized aluminum or nickel-plated brass. The internal pneumatics are low-maintenance and designed for long-term reliability.

Not sure how it works? Check out the tutorial videos in our instructions section.

Key Features

Technical Data

- Operating pressure: 0,5 - 10 bar (pneumatic system)

- Input pressure requirement: 44 l/min @5 bar (g)

- Tank pressure: -0,9 - 5 bar (oil system)

- Tank volume: 0.35 L (replaceable)

- Connections: NW7 (INPUT) and NW5 (OUTPUT)

- Operating type: pneumatic, no electrical power required

VENTURI Vacuum

Our Vacuum Bleeder creates a controlled vacuum up to -0,9 bar (rel) with a Venturi nozzle. The pneumatic system relies on an input pressure of 4,5 bar to reach maximum vacuum.

Quick Connections

The system features a quick-change mechanism for the oil tank and oil hose.

This makes switching between different oils easy, simply use a separate tank or oil hose for each suspension fluid.

Environmentally Conscious

The VENTURI uses renewable and recyclable materials wherever possible — including wood composites and fully recyclable aluminum and stainless steel. Packaging is plastic-free, based on recycled cardboard and paper-based cushioning, keeping the environmental footprint minimal without compromising protection.

Regional Production

All proprietary VENTURI components are manufactured in Tirol. High-precision CNC partners machine the aluminum and stainless-steel parts, while local sheet-metal specialists produce the housing elements. The wooden components are CNC-milled in a protected workshop environment, ensuring both precision and social value. Regional production keeps quality high, logistics short, and every unit traceable back to its origin.